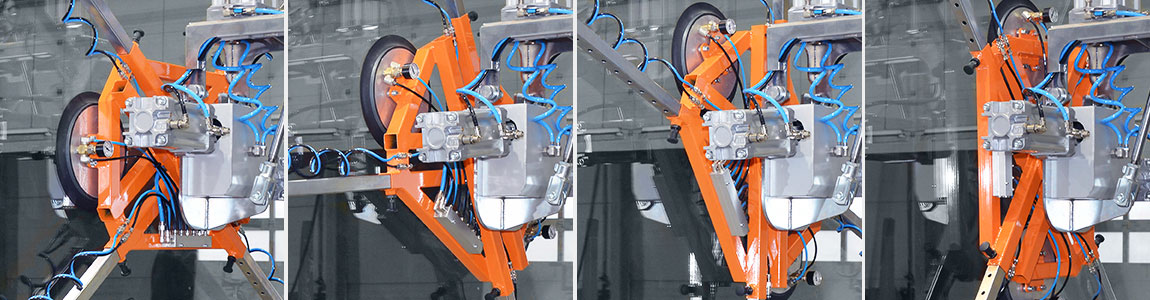

Rigidly guided manipulators

Safety features

- Compliance with all criteria of DIN EN 13155

- Devices for internal handling of glass according DIN EN 13035

- CE mark according to Machinery Directive 2006/42/EG

- Devices with dual-circuit vacuum systems for construction site use

- Each vacuum circuit with 2-fold safety

- Integrated vacuum gauges

- Optical and/or acoustic warning devices signaling deviations from the nominal condition

- Pressure controlled vacuum to reduce the consumption of energy and compressed air

- Integrated pressure switch control to indicate malfunctions

- Construction site devices with 24 V battery systems with considerably increased safety compared to 12 V systems

- Battery devices with built-in battery level indicator

- Vacuum reservoir to compensate vacuum loss

- Energy-self-sufficient indicator to signal breakdown of energy supply

Legende

X-Y lightweight crane systems

X-Y lightweight crane systems Column- and wall-mounted slewing cranes

Column- and wall-mounted slewing cranes For even glass panes

For even glass panes Rotate 360°

Rotate 360° Rotate +/- 90°

Rotate +/- 90° Rotate 90°/95°

Rotate 90°/95° Turn-over ≥ 180°

Turn-over ≥ 180° Turn-over 0 - 96°/98°

Turn-over 0 - 96°/98° Tilt around horizontal axis

Tilt around horizontal axis Incline 82°/84° - 90°

Incline 82°/84° - 90° telescopic boom/crane arm/lifting column

telescopic boom/crane arm/lifting column Mains current

Mains current Compressed air

Compressed air